The Art of Polishing: A Comprehensive Guide to Jewelry Buffing Wheels

Related Articles: The Art of Polishing: A Comprehensive Guide to Jewelry Buffing Wheels

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Art of Polishing: A Comprehensive Guide to Jewelry Buffing Wheels. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Art of Polishing: A Comprehensive Guide to Jewelry Buffing Wheels

- 2 Introduction

- 3 The Art of Polishing: A Comprehensive Guide to Jewelry Buffing Wheels

- 3.1 Understanding the Essence of Jewelry Buffing Wheels

- 3.2 The Anatomy of a Jewelry Buffing Wheel

- 3.3 The Diverse Applications of Jewelry Buffing Wheels

- 3.4 Choosing the Right Jewelry Buffing Wheel

- 3.5 Masterful Techniques for Using Jewelry Buffing Wheels

- 3.6 Frequently Asked Questions about Jewelry Buffing Wheels

- 3.7 Tips for Using Jewelry Buffing Wheels Effectively

- 3.8 Conclusion

- 4 Closure

The Art of Polishing: A Comprehensive Guide to Jewelry Buffing Wheels

Jewelry buffing wheels are essential tools in the world of jewelry making and restoration. They play a crucial role in achieving a flawless, lustrous finish on metal surfaces, enhancing the beauty and value of any piece. This comprehensive guide delves into the intricacies of these specialized wheels, exploring their construction, applications, and the art of using them effectively.

Understanding the Essence of Jewelry Buffing Wheels

At its core, a jewelry buffing wheel is a specialized abrasive tool designed for polishing and smoothing metal surfaces. Unlike conventional abrasive tools, buffing wheels utilize a soft, flexible material to gently remove surface imperfections while imparting a high-gloss finish.

The Anatomy of a Jewelry Buffing Wheel

A jewelry buffing wheel consists of three primary components:

- The Wheel: This is the core of the tool, typically made of a durable material like wood, plastic, or metal. The wheel’s diameter and shape vary depending on its intended use, ranging from small, handheld wheels to larger, motorized versions.

- The Buffing Compound: This is the abrasive material applied to the wheel. It comes in various grades, each designed for specific polishing tasks. Common buffing compounds include rouge, tripoli, and white diamond compound, each with its unique abrasive properties.

- The Mandrel: This is a metal shaft that connects the wheel to the buffing machine. The mandrel’s size and threading must match the wheel and the buffing machine for a secure and stable connection.

The Diverse Applications of Jewelry Buffing Wheels

Jewelry buffing wheels are versatile tools with a wide range of applications in the jewelry industry, including:

- Polishing: Buffing wheels are indispensable for achieving a mirror-like finish on various metals, including gold, silver, platinum, and stainless steel. They remove scratches, blemishes, and other imperfections, revealing the metal’s natural brilliance.

- Cleaning: Buffing wheels can effectively remove tarnish, oxidation, and other surface contaminants from jewelry pieces, restoring their original luster.

- Finishing: Buffing wheels play a crucial role in achieving specific finishes, such as satin, matte, or brushed finishes, depending on the type of buffing compound used.

- Removing Burrs: These wheels can effectively remove burrs and sharp edges left behind after cutting or shaping jewelry pieces, ensuring a smooth and safe final product.

Choosing the Right Jewelry Buffing Wheel

Selecting the appropriate buffing wheel for a specific task requires considering several factors:

- Metal Type: Different metals require different buffing compounds and wheel types. For example, softer metals like silver may require a gentler approach than harder metals like gold.

- Desired Finish: The desired finish dictates the choice of buffing compound and wheel. A mirror-like finish requires a finer compound and a soft wheel, while a brushed finish may necessitate a coarser compound and a harder wheel.

- Wheel Size and Shape: The size and shape of the wheel are determined by the size and shape of the jewelry piece being polished. Smaller, handheld wheels are ideal for intricate pieces, while larger, motorized wheels are suitable for larger items.

- Buffing Compound Grade: The grade of the buffing compound determines the level of abrasion. Finer compounds are used for polishing and finishing, while coarser compounds are used for removing scratches and imperfections.

Masterful Techniques for Using Jewelry Buffing Wheels

Using jewelry buffing wheels effectively requires practice and a keen understanding of their nuances. Here are some key techniques to master:

- Proper Wheel Selection: Selecting the right wheel and compound is crucial for achieving the desired results.

- Consistent Pressure: Applying even pressure throughout the buffing process is essential for a uniform finish. Excessive pressure can damage the metal surface.

- Proper Speed: The buffing speed should be adjusted based on the metal type and the desired finish. Higher speeds are suitable for polishing, while lower speeds are better for finishing.

- Cooling: Excessive heat can damage the metal and the buffing wheel. It’s essential to cool the metal and the wheel periodically with water or a lubricant.

- Cleanliness: Maintaining a clean workspace and clean tools is vital for achieving a flawless finish.

Frequently Asked Questions about Jewelry Buffing Wheels

Q: What are the different types of jewelry buffing wheels?

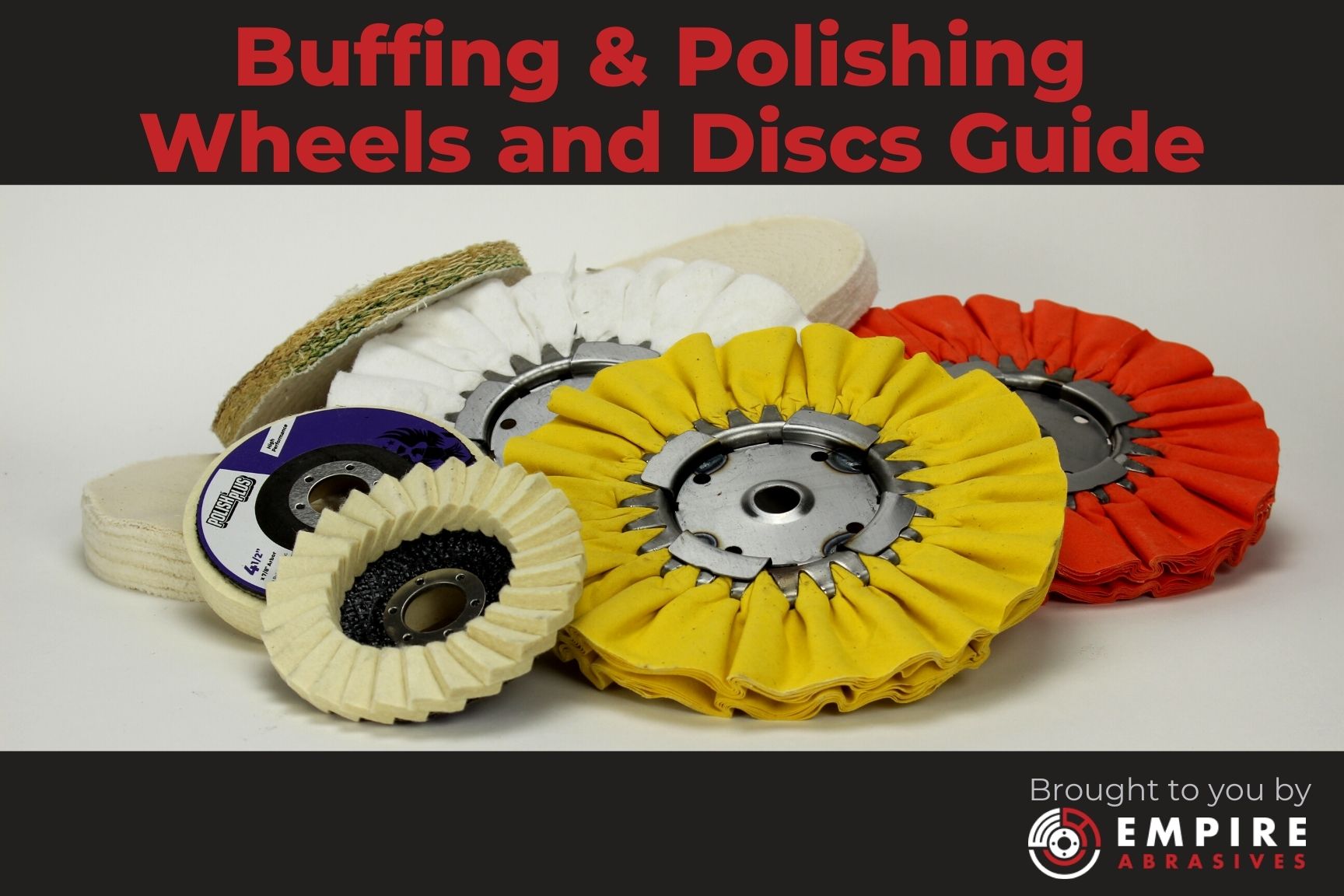

A: Jewelry buffing wheels come in various types, each designed for specific applications. Common types include:

- Canvas Wheels: These wheels are made of tightly woven canvas and are ideal for polishing and finishing softer metals.

- Felt Wheels: Felt wheels are soft and flexible, making them suitable for delicate jewelry pieces.

- Leather Wheels: Leather wheels are more durable than felt wheels and are often used for polishing harder metals.

- Sisal Wheels: Sisal wheels are made from natural fibers and are used for removing scratches and imperfections.

Q: What is the best way to clean a jewelry buffing wheel?

A: It is essential to clean jewelry buffing wheels regularly to remove accumulated debris and maintain their effectiveness. The cleaning process depends on the type of wheel:

- Canvas and Felt Wheels: These can be cleaned with a brush and soapy water.

- Leather Wheels: Leather wheels can be cleaned with a damp cloth or a leather cleaner.

- Sisal Wheels: Sisal wheels should be brushed to remove debris.

Q: How do I know if I’m using the correct buffing compound?

A: The choice of buffing compound depends on the metal type, the desired finish, and the level of abrasion required.

- Rouge: Rouge is a fine compound used for polishing and finishing softer metals like silver and gold.

- Tripoli: Tripoli is a slightly coarser compound used for removing scratches and imperfections from harder metals like platinum.

- White Diamond Compound: White diamond compound is a very fine compound used for achieving a mirror-like finish.

Q: Can I use a jewelry buffing wheel on any metal?

A: While jewelry buffing wheels are versatile, they are not suitable for all metals. Some metals, such as aluminum, are more susceptible to scratching and should be polished using alternative methods.

Tips for Using Jewelry Buffing Wheels Effectively

- Start with a Coarse Compound: Begin with a coarser compound to remove significant scratches and imperfections before moving to finer compounds for polishing and finishing.

- Use Light Pressure: Excessive pressure can damage the metal surface and the buffing wheel. Apply consistent, light pressure throughout the buffing process.

- Avoid Overheating: Overheating can damage the metal and the buffing wheel. Cool the metal and the wheel periodically with water or a lubricant.

- Keep the Wheel Clean: Regularly clean the buffing wheel to remove accumulated debris and maintain its effectiveness.

Conclusion

Jewelry buffing wheels are essential tools for achieving a flawless, lustrous finish on metal surfaces. Understanding their construction, applications, and proper usage techniques is crucial for maximizing their effectiveness and creating stunning jewelry pieces. By mastering the art of using these specialized tools, jewelers can elevate their craftsmanship and create pieces that are both beautiful and durable.

Closure

Thus, we hope this article has provided valuable insights into The Art of Polishing: A Comprehensive Guide to Jewelry Buffing Wheels. We thank you for taking the time to read this article. See you in our next article!